Key Takeaways

- Artificial intelligence (AI) and machine learning (ML) are elevating data analysis in pigging operations, allowing for quicker, more accurate detection of issues within pipelines.

- Miniaturized and modular pigs are opening up access to pipelines that were once considered impossible to inspect due to size or complexity constraints, ensuring even older or intricate assets can be maintained.

- Real-time collection and cloud-based data platforms are drastically improving both field-level monitoring and high-level decision making, creating a more agile and responsive inspection process.

- Advancements in robotics are further advancing the adaptability and precision of pipeline inspection technologies, enabling thorough assessments in previously inaccessible areas.

Introduction

Pipeline pigging remains a foundational practice in the maintenance and integrity management of oil and gas infrastructure. In the past, pigging was primarily a mechanical operation, often focused solely on removing debris and basic internal cleaning. However, recent years have witnessed remarkable progress driven by new technology, advanced data integration methods, and the evolution of more innovative inspection tools. These changes have resulted in unprecedented efficiency, reliability, and insight for pipeline operators. These advancements are enhancing asset lifespan and reducing operational costs by streamlining routine inspection cycles and contributing to a safer, more sustainable energy sector. For companies seeking the most advanced options in pipeline pigs for natural gas systems, the latest techniques and products are transforming what’s possible in even the most challenging environments. Investments in research and development by industry leaders mean end-users can count on continuous improvement, future-proofing their infrastructure against new challenges.

Ongoing innovations in pig design and digital data management enhance inspection quality and efficiency in pipeline operations. New technologies allow operators to achieve thorough inspections while minimizing downtime and risks of failures. Integrated systems utilizing various sensor types accelerate inspection processes and provide actionable insights, setting a new industry standard for pipeline asset management. Real-time data sharing fosters collaborative decision-making among field operators and engineers, enabling timely responses to anomalies and improved resource allocation. Embracing these advancements enhances safety and operational efficiency and simplifies regulatory compliance. Adopting cutting-edge technologies offers companies competitive advantages and builds trust with stakeholders amidst market fluctuations.

AI and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) technologies is revolutionizing the way pipeline pigging operations handle inspection data. Instead of relying on slow and sometimes subjective manual review, AI-powered systems can process enormous datasets at extraordinary speeds, automatically interpreting signals and detecting subtle patterns or anomalies that could indicate early-stage pipeline defects. These AI algorithms are trained to flag issues such as corrosion, cracks, wall loss, and deformations—all in real time, often before a human inspector could spot them. With AI-driven predictive models, operators can now anticipate failures or leaks before they occur, enabling them to schedule maintenance proactively and minimize unplanned outages or costly emergency repairs. This combination of smarter data analytics and predictive maintenance strategies marks a major step forward for operational dependability and cost efficiency across the industry. For example, advancements highlighted by Bloomberg showcase how intelligent pigging tools, enhanced by machine learning, are rapidly adopted by major energy operators worldwide to prevent leaks, reduce downtime, and ensure continuous pipeline health. This unprecedented analytical power also supports compliance, making it easier to meet regulatory standards and demonstrate pipeline integrity to auditors or stakeholders.

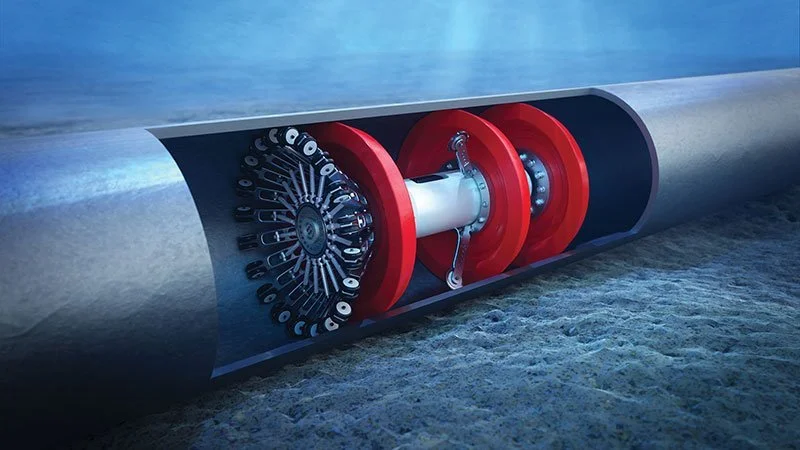

Miniaturized and Modular Pigs

Innovation in pig design has expanded the accessibility of pigging technology to pipelines that were previously considered too narrow or complex for inspection. Traditional pigs were often too large, rigid, or inflexible to travel through tight bends, diameter changes, or older pipelines with irregular geometries. Today, modern miniaturized pigs use advanced materials and flexible, modular construction techniques, which enable them to traverse tortuous or aging pipeline sections without becoming stuck or missing key inspection points. This breakthrough ensures that even legacy infrastructure benefits from regular, thorough inspection—supporting compliance and safety goals industry-wide. Modular pigs can be customized with specialized sensor arrays and adjusted for different lengths or diameters, so a single tool can tackle various inspection challenges within a network. Companies investing in these adaptive pigs can now promote lifecycle asset management on what were once branded as “unpiggable” lines, increasing inspection coverage and minimizing the risk of undetected pipeline issues that could lead to expensive failures or environmental hazards. More on how smaller robots are entering the most challenging environments can be found in Forbes’ technology insights. These technological advances open new revenue and safety opportunities for pipeline owners worldwide.

Real-Time Data Collection and Cloud Integration

The digitalization of pigging operations has yielded significant benefits, particularly in the areas of data transfer, reliability, and collaboration. Today’s leading pigging systems are equipped with multitechnology platforms capable of handling multiple inspection techniques—such as magnetic flux leakage, ultrasonic testing, and geometry—in a single pigging run. By integrating cloud-based solutions into these systems, field teams can upload and share data in real time, granting engineers and asset managers near-instant access to inspection summaries and raw performance indicators from anywhere in the world. This reduces downtime by eliminating the need to physically deliver storage devices or report findings long after the inspection is complete. As a result, reporting is accelerated, compliance paperwork is simplified, and issues can be tracked from discovery to resolution without delay. Since all stakeholders can access synchronized data almost instantly, operation teams are empowered to respond to findings while the pig is still in the field, driving an altogether smarter workflow from end to end. Additionally, historical data is easier to aggregate and analyze, revealing long-term trends and assisting with future planning and risk assessment, thus protecting critical pipeline assets.

Robotic Inspection Systems

The emergence of robotic inspection devices has redefined what’s achievable within pipeline monitoring, with sophisticated features that go far beyond previous generations of pigging tools. Highly maneuverable, remotely operated robots equipped with advanced sensors and actuators can travel through bends, welds, and complex connections that were previously inaccessible to traditional pigs. For instance, robotic crawlers utilizing circumferential magnetic flux leakage or high-resolution ultrasonic mapping technologies are now capable of inspecting critical seams, girth welds, and lateral connections, quickly detecting corrosion, stress cracking, and other subtle or early-stage structural defects on the spot. These robots function in real-world environments without extensive modifications to pipeline infrastructure, and can be operated from remote locations to minimize on-site hazards. Effectively, these robots enable asset owners to tackle even the most intricate pipeline configurations, ensuring full system integrity and early intervention when required. Automated robotic systems are also reducing the need for large crews or hazardous entry procedures, supporting higher safety standards in the energy industry.

Conclusion

Pipeline pigging technology is advancing rapidly—driven by automation, AI analytics, and state-of-the-art design. As a result, operators gain unparalleled visibility, precision, and efficiency when safeguarding vital pipeline assets. The combination of smarter data analysis, adaptive inspection tools, and real-time collaboration platforms transforms how pipelines are monitored and maintained. Staying at the forefront of these trends not only protects critical infrastructure from avoidable failures but also supports a safer, more resilient energy sector for all stakeholders involved. By investing in these innovative pigging approaches, companies can achieve long-term operational excellence and build trust across the industry and beyond.