Key Takeaways

- Implementing lean manufacturing principles is fundamental to reducing waste and enhancing productivity.

- Agile manufacturing practices foster adaptability and resilience in the face of changing market landscapes.

- Advanced technologies, including AI and IoT, are transforming operational decision-making and efficiency.

- Digital twins and predictive analytics support continuous improvement and proactive process optimization.

- Just-in-time manufacturing ensures alignment of production with demand, reducing overstock and waste.

In the ever-competitive industrial landscape, the ability to innovate and refine manufacturing methods is more crucial than ever. Companies striving for operational excellence are embracing cutting-edge strategies to drive efficiency, minimize waste, and meet market demands with precision. Among the most effective tactics are lean manufacturing principles, agile methodologies, and the integration of smart technologies. Partnering with a certified machine shop Houston, TX can be a key advantage in gaining access to modern, optimized manufacturing solutions and high standards of quality.

These contemporary strategies not only yield greater productivity but also provide a pathway toward environmental stewardship, cost savings, and long-term sustainability. From real-time analytics to rapid reconfiguration of production lines, manufacturers are leveraging digital tools to overcome traditional bottlenecks and adapt quickly to disruptions. Embracing such approaches is the foundation of enduring success in today’s manufacturing sector.

Embracing Lean Manufacturing Principles

Lean manufacturing is the cornerstone of process efficiency in modern factories. Its core tenet—eliminating activities that do not add value—enables businesses to streamline workflows, reduce cycle times, and cut operating costs. Lean methodologies such as value stream mapping and 5S help pinpoint redundancies, while tools like Kanban support smoother inventory management. By optimizing inventory levels and minimizing overproduction, manufacturers unlock cost savings and improve their environmental footprint. Companies worldwide, from automotive leaders to electronics giants, have successfully adopted lean principles to deliver both economic and sustainability benefits.

Adopting Agile Manufacturing for Flexibility

The volatile nature of global markets, fluctuating consumer expectations, and unexpected disruptions demand a flexible production environment. Agile manufacturing emphasizes adaptability, enabling organizations to respond rapidly to new opportunities or challenges. Cross-functional teams, modular production lines, and flexible supply chains are key characteristics of agile operations. These features enable manufacturers to quickly shift direction, scale output, or modify product specifications at minimal cost. By fostering an agile mindset, companies cultivate resilience and encourage continual process improvement throughout the enterprise.

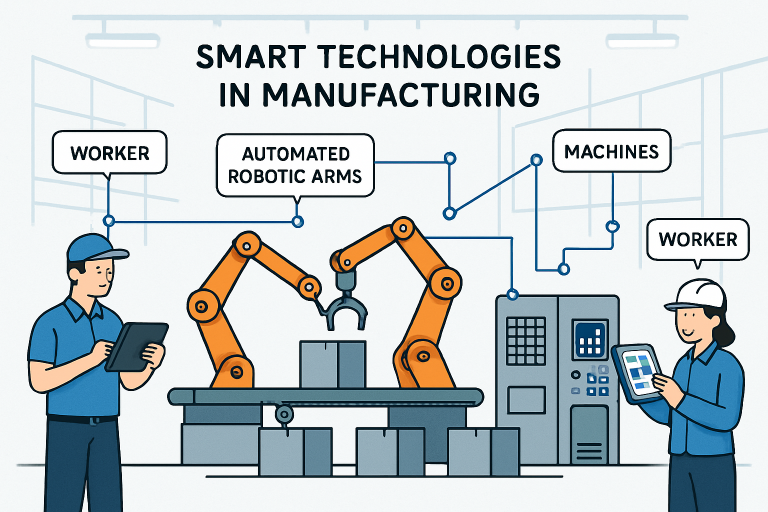

Integrating Advanced Technologies

The integration of artificial intelligence and the Internet of Things (IoT) has ushered in a new era for manufacturing. AI-driven insights facilitate predictive maintenance, anomaly detection, and dynamic process optimization. Meanwhile, IoT devices gather real-time data on machine performance, energy consumption, and quality outputs, empowering managers to make data-driven adjustments on the fly. For example, automated alerts can instantly notify teams of irregularities, thereby reducing downtime and maintaining high-quality output.

Utilizing Digital Twins for Dynamic Reconfiguration

Digital twins are virtual representations of physical assets and processes, enabling simulation and analysis before changes are made on the factory floor. By leveraging data from IoT sensors and AI systems, these digital models support dynamic reconfiguration of production lines to optimize workflows, test “what-if” scenarios, and prepare for disruptions without interrupting operations. Companies benefit from reduced development cycles, minimized prototyping costs, and improved responsiveness to external stresses. The adoption of digital twins is increasingly seen as essential for future-ready manufacturing.

Implementing Just-in-Time Manufacturing

Just-in-time (JIT) manufacturing is essential for reducing waste and aligning production with real-time customer demand. With JIT, materials and components are ordered and received only when needed, lowering inventory costs and preventing excess. Accurate demand forecasting and strong supplier relationships are key to JIT success. However, since the method heavily depends on a smooth supply chain, risk assessment and contingency planning are crucial to maintaining continuous production during supply disruptions or demand changes. JIT remains an effective strategy when combined with risk-mitigation measures.

Enhancing Workflow with Predictive Analytics

Predictive analytics leverages historical data to anticipate trends and identify potential production issues, allowing manufacturers to resolve challenges before they impact output. AI-powered monitoring can detect early signs of equipment failure or quality degradation, enabling proactive scheduling of maintenance or adjustments to processes. Such foresight minimizes unexpected downtime, maximizes resource utilization, and maintains product quality.

Leveraging 3D Printing for Customization

3D printing, also referred to as additive manufacturing, has revolutionized prototyping and small-batch production. Manufacturers can now iterate designs quickly, accelerate development cycles, and produce custom components with minimal material waste. This technology’s flexibility supports personalized products, shortens time-to-market, and reduces costs for bespoke manufacturing runs, granting companies a significant competitive advantage.

Conclusion

Modernizing manufacturing processes through the adoption of lean and agile practices, advanced technologies, digital twins, and predictive analytics is not only a pathway to higher efficiency but also the key to long-term resilience in a dynamic marketplace. By integrating these approaches, manufacturers can improve operational performance, adapt to disruptions, and foster a culture of continuous innovation, all while ensuring sustainable growth and value creation.