Table of Contents

- Automation and Robotics

- Advanced Conveyor Systems

- Data Analytics and IoT Integration

- Energy-Efficient Technologies

- Customization and Flexibility

- Human-Machine Collaboration

Efficient bulk material handling has become essential for any operation seeking to remain competitive in today’s rapidly evolving industrial landscape. From manufacturing plants to food processors, companies are seeking out smarter and more sustainable methods to handle, move, and process large quantities of material. The introduction of advanced technologies, including automation and intelligent data systems, is transforming the industry, enabling facilities to optimize their productivity while minimizing risk. As industries modernize, solutions such as industrial blenders are proving indispensable, simplifying tasks and boosting both throughput and accuracy.

As the demand for higher standards in quality and efficiency intensifies, businesses are increasingly investing in bulk material handling solutions that do more than move products from point A to point B. With new trends focused on integrating smart controls, optimizing for energy efficiency, and improving human-machine collaboration, the sector is transforming how workers interact with their environments. Advanced handling equipment, enabled by real-time analytics and customization options, is now fundamental to success, fostering a safer and more productive work environment in facilities of all sizes.

Forward-thinking companies are harnessing the full potential of bulk handling solutions not only for greater efficiency but also for cost savings and a reduced environmental footprint. With markets demanding ever-greater agility in production and distribution, staying ahead requires adopting new strategies and a willingness to innovate.

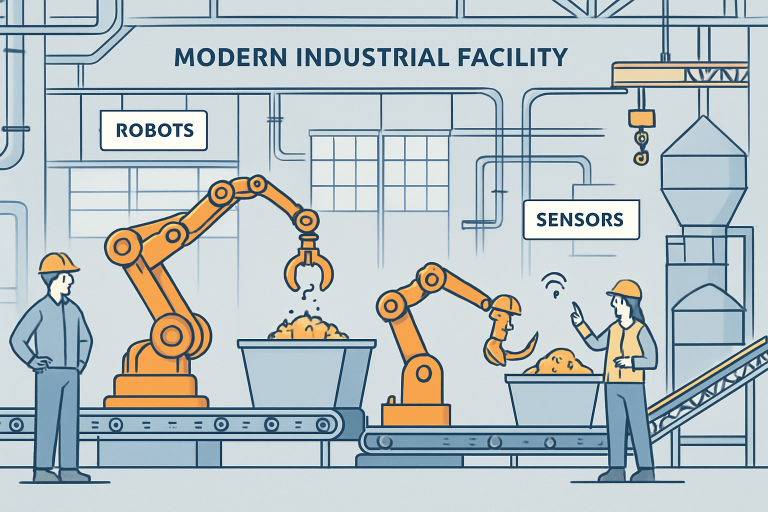

Automation and Robotics

Automation and robotics have become crucial pillars in modern bulk material handling. Facilities worldwide are deploying Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) to streamline the transportation of bulk materials. By utilizing intelligent navigation and obstacle-avoidance systems, these robots can operate safely in dynamic environments, handling a range of materials from dense powders to delicate packaging. Automation not only speeds up operations but drastically reduces the risk of workplace injuries. As robotics technology continues to mature, investments in these systems are expected to surge, further fueling the shift toward “lights-out” manufacturing facilities running with minimal human oversight.

Advanced Conveyor Systems

Technological advancements have significantly enhanced the capability and efficiency of conveyor systems. Innovations such as magnetic propulsion, used by pioneering companies, have allowed for the precise and emission-free movement of materials through facilities. These systems deliver quiet, efficient, and low-maintenance operation, capable of moving loads of up to hundreds of kilograms. Furthermore, modern conveyor installations often feature modular designs that can be rapidly adapted to suit different product flows or material types, making them indispensable for industries that must remain agile in response to shifting production needs.

Data Analytics and IoT Integration

The integration of Internet of Things (IoT) devices and data analytics is transforming every element of bulk material handling. By embedding sensors in conveyors, blenders, hoppers, and transport vehicles, facilities can now access immediate operational data. This stream of information enables predictive maintenance, real-time inventory tracking, and efficiency optimizations. For example, analytics software can spot bottlenecks and suggest process improvements, while predictive alerts help prevent costly equipment failures. The outcome is a data-driven work environment that responds proactively to trends and minimizes downtime.

Recent research from McKinsey & Company highlights the significant gains that can be achieved when analytics and IoT are fully integrated into manufacturing and logistics operations, resulting in increased productivity and reduced energy consumption.

Energy-Efficient Technologies

With industrial energy costs on the rise and environmental standards tightening, energy efficiency is now serious business. Many new conveyor installations include regenerative braking systems that recover and reuse kinetic energy. Manufacturers are rapidly shifting to solar or hybrid power sources for material transport vehicles and equipment. Even compact devices, such as industrial blenders, are now engineered for lower power consumption without compromising performance, thereby supporting global sustainability goals. The steady switch to electric-powered fleets not only reduces emissions but can also lead to significant operational savings over time.

Customization and Flexibility

Today’s handling systems are built for flexibility. Modular construction and quick-change components allow operators to reconfigure a production line or facility layout with minimal downtime or expense. Especially for industries that process multiple materials or have batch requirements, this customization is invaluable. State-of-the-art robotic systems are now capable of detecting and adapting to new product types or packaging shapes in real-time, thereby minimizing the need for manual intervention. Such flexibility ensures that production can quickly pivot to meet changes in demand or new industry protocols—an essential advantage in unpredictable marketplaces.

Human-Machine Collaboration

Rather than replacing human workers, today’s robotics and “cobot” solutions are designed to complement them. Collaborative robots work alongside people, taking on repetitive or hazardous tasks such as lifting, sorting, or palletizing, which helps reduce injuries and improve morale. With human operators handling exceptions and quality checks, the partnership between people and machines enables processing lines to be faster, more responsive, and safer. Facilities that embrace this collaboration gain a workforce that is both empowered and augmented, ready for modern challenges.

This new era of bulk material handling combines technological sophistication with practical advantages—driving safer, smarter, and more productive industrial facilities than ever before.