Table of Contents

- Structural Integrity and Material Quality

- Compatibility with Motion Compensation Systems

- Design Efficiency for Additional Equipment

- Load Capacity and Customization

- Compliance with Industry Standards

- Advanced Control Systems

- Preventative Maintenance Features

- Safety Enhancements

- Final Thoughts

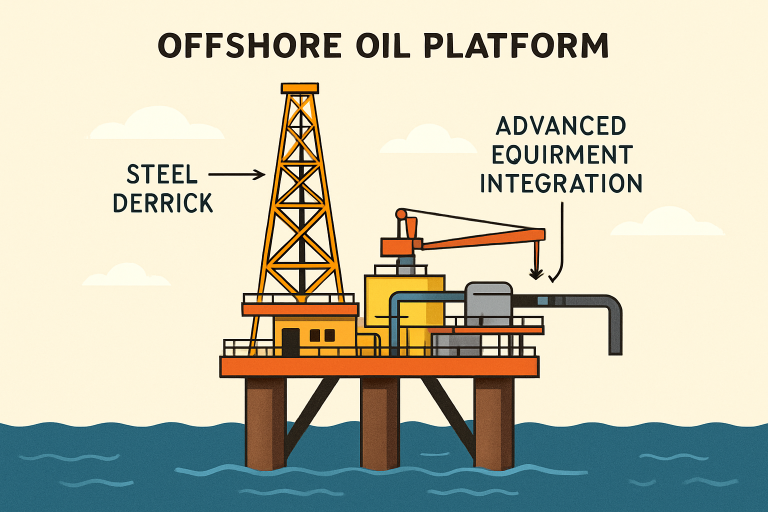

Selecting the right dynamic derrick system for offshore drilling is essential for optimizing processes, minimizing risks, and ensuring the longevity of your equipment. A decision grounded in robust criteria can have a direct, positive impact on crew safety and overall operational effectiveness. Before investing, it’s important to review the features that define an effective system designed for the world’s most demanding drilling environments. Many drilling companies opt for an oil drilling derrick designed for offshore platforms to maximize stability and performance under harsh oceanic conditions.

Offshore platforms are exposed to constant movement and high stress loads; therefore, the derrick system must utilize advanced materials and technologies. The right choice enhances efficiency, protects investments in additional drilling equipment, and ensures compliance with strict industry standards over time. Understanding these requirements will position your drilling operation for success – while also protecting personnel and assets.

Structural Integrity and Material Quality

The durability and safety of a dynamic derrick system begin with its structural integrity. Look for derricks constructed from premium, high-grade steel certified by recognized international standards for use in low-temperature and corrosive marine conditions. Material selection is vital because the derrick must resist not only extreme weather but the hull motions of semisubmersibles, drill ships, and jack-up rigs in action or while under tow. Durable material means fewer repairs and replacement cycles, leading to less downtime and lower lifetime costs.

Compatibility with Motion Compensation Systems

Modern offshore drilling environments are never static, with platforms constantly in motion due to waves, wind, and currents. A high-quality dynamic derrick system should allow seamless integration with motion compensators, power swivels, and advanced pipe-racking equipment. This compatibility supports drilling efficiency and security, reducing wear and tear on machinery and helping protect workers during rough sea conditions.

Design Efficiency for Additional Equipment

With the evolution of drilling technology, the integration of additional equipment, such as top drives and pipe-handling systems, is becoming increasingly important. An efficient derrick design should provide enough clearance, support, and modularity to accommodate these tools without compromising overall derrick performance. Streamlined integration from the outset ensures the ability to upgrade with emerging technologies, helping drilling operators remain competitive as the industry evolves.

Load Capacity and Customization

Determining maximum static hook load is a fundamental step in selecting a derrick, as each operation will have its unique demands. Customization allows the derrick to be engineered for a specific project, enhancing operational safety and reducing unforeseen failures. Modular features, tailored dimensions, and add-on components expand the derrick’s functional envelope, ensuring it precisely meets the operational needs of each project.

Compliance with Industry Standards

Adherence to industry standards is crucial for ensuring equipment safety, reliability, and optimal performance. Look for a derrick system that is monogrammed in accordance with API Specification 4F. This guarantees the system has undergone independent quality assessments and meets or exceeds safety, environmental, and operational criteria required for modern oil and gas operations.

Advanced Control Systems

Automation and precision are must-have features for today’s dynamic derrick systems. Look for control panels featuring multi-functional joystick layouts, LCD screens with real-time diagnostics, and hydraulic pressure monitoring. Advanced controls not only make operations more efficient but also provide the operator with more information to prevent incidents and enhance safety. These features collectively boost productivity while reducing the risk of system errors.

Preventative Maintenance Features

Easy maintenance is crucial for maximizing uptime and minimizing disruptions. Sought-after derricks incorporate accessible components, simple diagnostic interfaces, and maintenance information that enable the crew to quickly identify wear, perform repairs, and schedule regular checkups. Investing in a derrick with strong preventative maintenance features helps extend its operational life and reduces the frequency of unexpected failures. According to Offshore Magazine, enhanced maintainability is strongly correlated with reduced operational downtime in offshore environments.

Safety Enhancements

Safety technologies are essential for protecting not only the crew but also capital investments in offshore drilling assets. Look for features such as lanyard detection systems that require confirmation of harnesses before initiating operations, as well as live load monitoring to prevent exceeding critical thresholds. These built-in protections curb human error and offer real-time warnings that prevent structural compromise or injury. A focus on safety safeguards workers and maintains regulatory compliance.

Final Thoughts

Choosing the right dynamic derrick system is more than a technical decision—it is a strategic investment in the long-term safety, productivity, and resilience of offshore drilling operations. By prioritizing structural integrity, compatibility with motion compensation technologies, and the ability to integrate additional equipment, operators ensure that their systems remain adaptable to the evolving demands of the industry. Compliance with recognized standards and the inclusion of advanced control features provide further confidence that the derrick will perform reliably, even under the harshest offshore conditions.

Equally important are preventative maintenance features and built-in safety enhancements, both of which contribute to reduced downtime and enhanced crew protection. A well-selected derrick system protects valuable assets, improves operational efficiency, and supports safer working environments. As offshore drilling challenges continue to grow in complexity, investing in a system designed with durability, innovation, and operational security at its core will position your operation for sustained success.